Bespoke LED Signs & Lighting for Commercial Use

With over 10 years of specialised experience in the field of LED lights, Focus LED UK Ltd has been providing affordable & excellent products for our end users.

Our Services start off from our workshop & offices based in Manchester near the city centre, we always provide solutions and quality products for our customers. We will listen, prepare and deliver to what the client require from start to finish. And we will only import high-quality products for large quantity order.

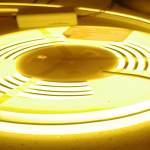

Over the 10 years LED Strip has been the most popular products for many construction fields. However, every project will require different lengths and type of LED Strip. Choosing the right product for you is what we do from start and in-order to deliver and to save you further time and money. We charge a very small fee for cutting and soldering LED Strip so that the only responsibility you have is to plug and play our finishing product.